Blog

Discover ORBRO’s latest technologies and updates.

All

Location Tracking

Vision AI

Technology Overview

Solutions

Case Studies

Others

What is Embedding? Decoding the Core Technology Behind AI and Its Global Applications

2025-12-28

Technology Overview

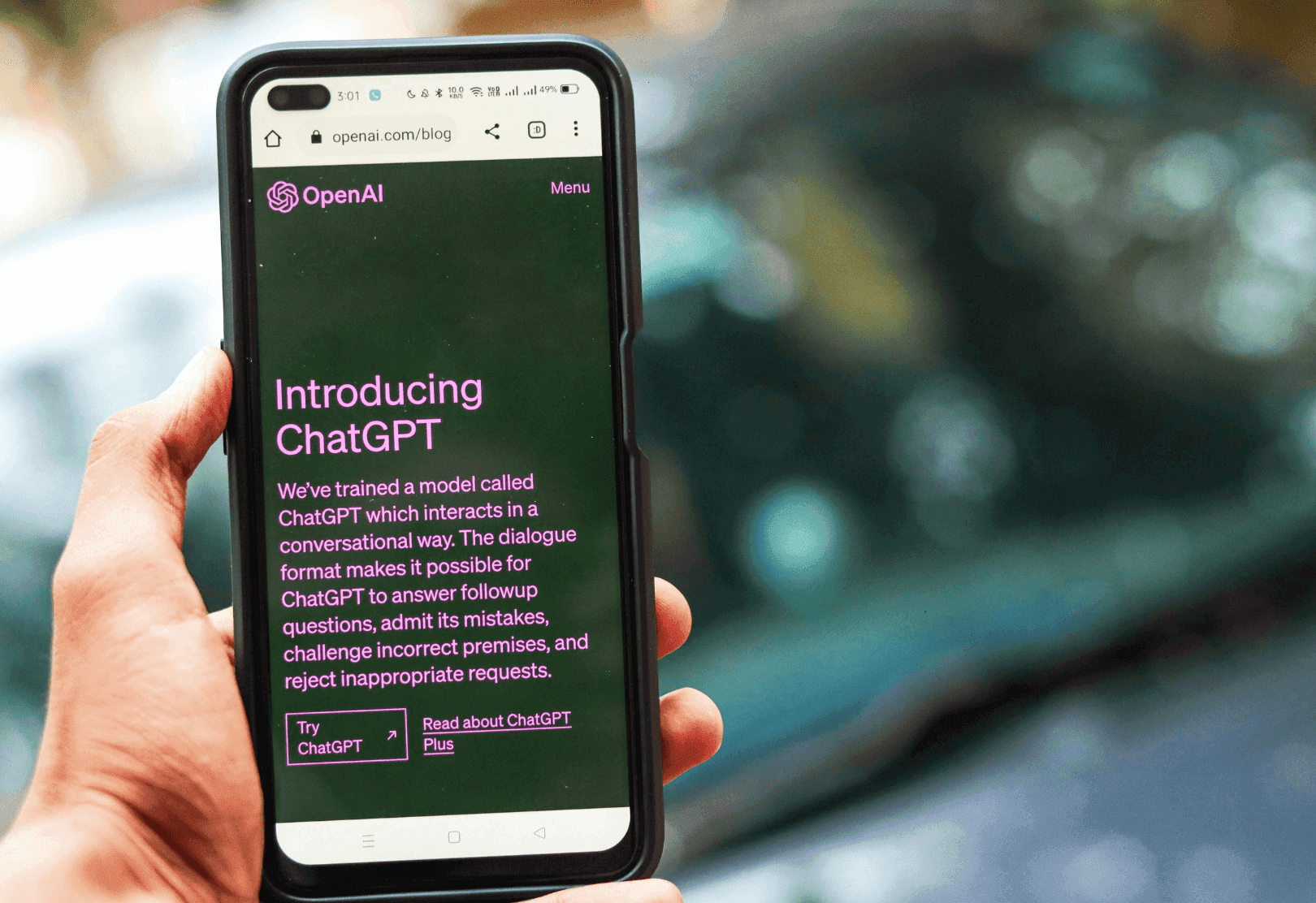

Generative AI in Enterprises: A Global Vision and a Breakthrough for B2B Operations

2025-12-02

Technology Overview

Agent vs Chatbot: What’s the Difference and Which Is Best for B2B Enterprises?

2025-11-17

Technology Overview

What Is a Chatbot? A Complete Guide to Benefits, Mechanisms, and Real-World Applications Worldwide

2025-11-09

Technology Overview

AI Agent for Enterprises: The Digital Workforce Reshaping the Future of Operations

2025-11-02

Solutions

What Is AI Automation? A Comprehensive Guide to Reshaping the Future of Enterprise Operations

2025-10-20

Technology Overview

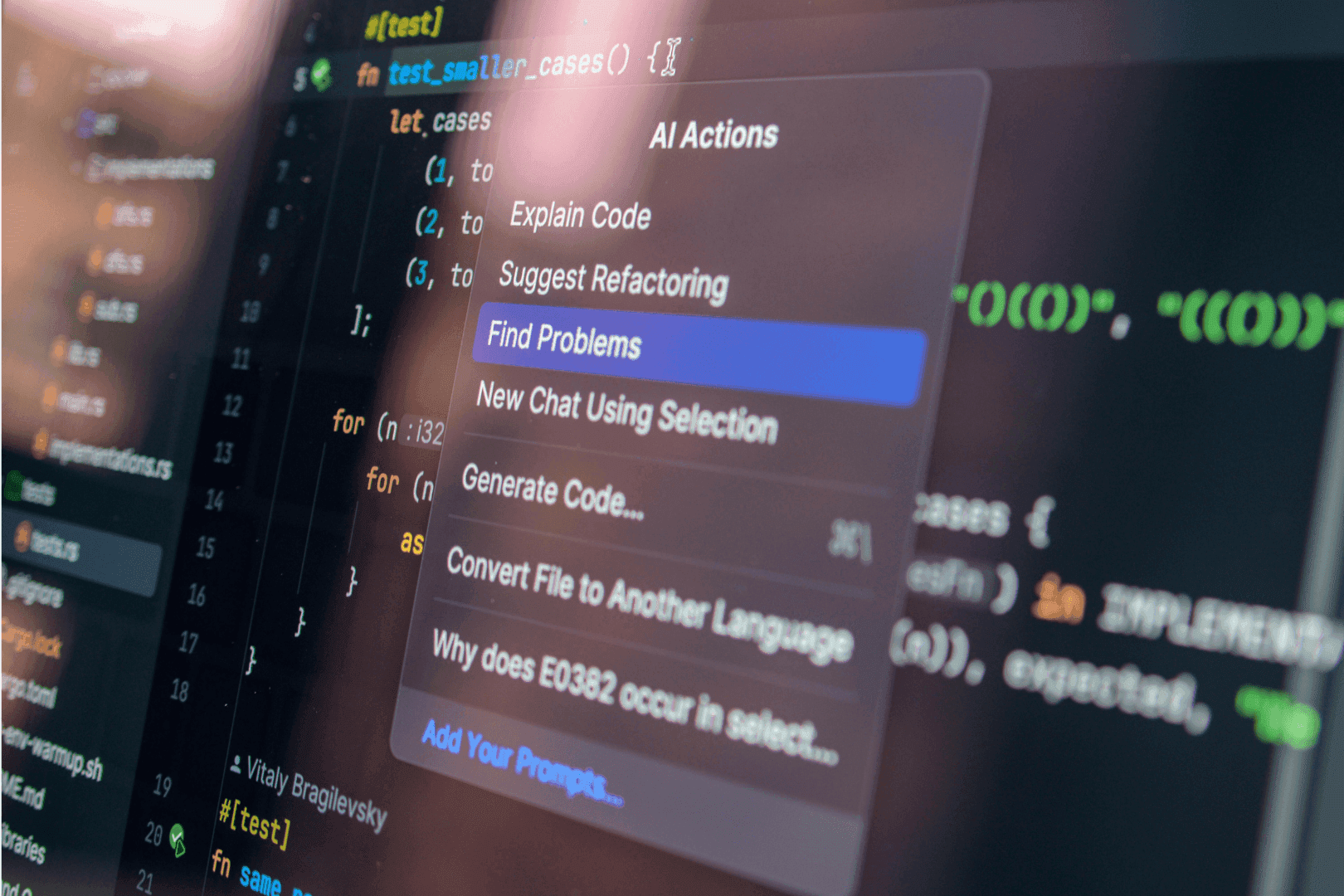

Decoding LLM for Enterprises: Turning Massive Data into a Core Competitive Advantage

2025-10-09

Technology Overview

Solutions

AI for Enterprises: The Comprehensive Answer to Operational Optimization and Revenue Breakthroughs

2025-10-03

Technology Overview

Solutions

What Is an NVR? Advantages of NVR in Surveillance Camera Systems

2025-07-09

Technology Overview

What Is CCTV? Classification and Its Role in the Digital Era

2025-07-08

Technology Overview

What Is UWB?

2025-07-08

Technology Overview

What Is Geofencing? What Benefits Can It Bring to Businesses?

2025-07-08

Technology Overview

What Are Logistics and Supply Chain Management?

2025-07-08

Solutions

What Is Digital Twin? Real-World Applications

2025-07-07

Solutions

What Is IPS? The Role of IPS in Technology

2025-07-07

Technology Overview

What Is Occupational Safety? Practical Measures to Ensure Workplace Safety

2025-07-07

Solutions

What Is a Smart City?

2025-07-07

Solutions

What Is an AI Camera? How Does It Work and What Are Its Benefits?

2025-07-07

Technology Overview

Solutions